Introduction

Precast girder concrete bridge are a very common structure used in North America. Precast concrete girders can be used for both new construction and rehabilitation projects. Precast concrete girders have many advantages including cost savings and speed of construction, but they also pose some challenges particularly when it comes to reinforcement detailing in 3D. In this article you will learn about precast concrete bridges and how to easily model them using Tekla Structures together with automated Bar Bending Schedule software from CYPE.

Precast girders concrete bridge

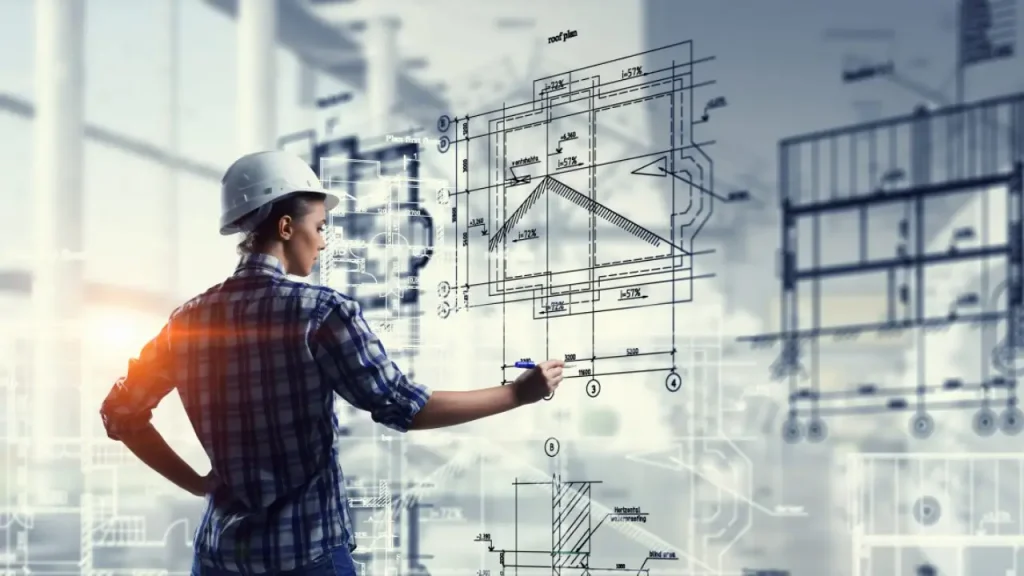

One of the most common types of bridges in North America are precast concrete bridge girders. Precast concrete bridges should always be modelled in 3D (for example as BIM) so you can use the 3D model for building information, quantity takeoffs, construction phasing and site logistics, material tracking and clash detection.

Precast concrete bridge girders are one of the most common types of bridges in North America. The following information is provided to help you model precast concrete bridge girders using Revit and other 3D BIM software:

- Precast concrete bridges should always be modelled in 3D (for example as BIM) so you can use the 3D model for building information, quantity takeoffs, construction phasing and site logistics, material tracking and clash detection.

A precast concrete girder bridge is a concrete beam that is formed off-site and then transported to the site to be installed on top of support columns or abutments.

Precast concrete girder bridges are a type of bridge that is made off-site, then transported to the site where it is installed on top of support columns or abutments. They have been used for over 100 years because they’re easy to transport and assemble, can be made in any shape, have a long lifespan and can be customized for specific applications.

The precast concrete girder bridges are also known as segmental beams or box girders because they are built from long pieces of steel or wood which form boxes/girders that resemble modern shipping containers. This makes it possible to carry out construction work while keeping traffic moving underneath the bridge using temporary supports until all parts are ready for installation at once at the final destination.

Advantages of Precast girder bridge

Precasting bridge girders has many advantages including cost savings and speed of construction, but they also pose some challenges particularly when it comes to reinforcement detailing in 3D.

Precasting bridge girders has many advantages including cost savings and speed of construction, but they also pose some challenges particularly when it comes to reinforcement detailing in 3D. As a designer, you will need to design the girders with adequate reinforcement given their size and complexity. This can present some difficulties as the precast girders are typically much larger than standard cast-in-situ (CIS) concrete beams which make them difficult to analyse using traditional 2D analysis tools such as SAP2000 or RISA3D®.

Precast girder bridges are usually large structures made up of multiple pieces that are then assembled on site before being lifted into place by cranes or self-propelled modular transporters (SPMT). Each individual segment is designed for particular loading conditions, so there is no single design that covers all cases.

Automated reinforcement module

Using an automated reinforcement module, you can easily create rebar cages for bridge girders within hours instead of days or even weeks.

Using an automated reinforcement module, you can easily create rebar cages for bridge girders within hours instead of days or even weeks. This can be a great help when your project is short on time and resources. In this article, we’ll take a look at how to use these features as well as some of their advantages and disadvantages.

How to easily model Precast Girder Bridge using Tekla Structures and automated Bar Bending Schedule software from CYPE.

Precast concrete bridges are built by pouring the concrete into a mold, which is then removed when the concrete has set. The process of manually removing the mold used to be very time consuming, but now there are automated systems that can do this process more efficiently than humans can at a fraction of the cost. This means that precast girders for large bridges can be modeled in a fraction of time compared with traditional methods.

The main advantage of using BIM (Building Information Modeling) for modelling precast girders is that it enables designers/engineers to collaborate with each other as well as contractors during design phase without having any issues with data consistency or losing track on files sent over email etc., which normally happens when sending large amounts of information via emails or FTP server etc.

Due to various reasons like not having access across different departments like structural engineers designing their part first then submitting it back again later after receiving approval from other departments such as electrical engineers designing theirs next etc., which results in multiple versions being created over time leading up until final approval has been given by everyone involved before proceeding further down stream towards construction stages since all parts must be finalized before beginning construction phase (construction drawings).

Modelling precast girder bridges

Modelling precast bridges is fast, easy and accurate when you use BIM software such as Tekla Structures together with automated BBS software from CYPE.

The combination of Tekla Structures and CYPE’s Bar bending schedule (BBS) software can help you model bridge girders easily by automating the process of creating bending schedules for precast concrete components such as beams and slabs. This can also include complex sections such as L-beams, Z-beams or T-beams where the shape of the part varies along its length.

Conclusion

Modelling precast bridges is fast, easy and accurate when you use BIM software such as Tekla Structures together with automated BBS software from CYPE.

Follow us to stay updated on LinkedIn, Facebook, Instagram and Twitter.